Norton Motorcycle Suspension

Norton Motorcycle Suspension Upgrades. Improve the suspension on your Commando, Atlas, or Twin. Replacement suspension components and upgrades on your Norton Commando. Improve the ride quality and the performance on your motorcycle.

Showing all 10 results

-

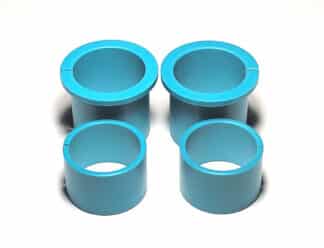

Super slippery longer lasting Turcite bushing set for Norton forks. Also see alum sleeves and damper upgrade.

$129.00 Select options -

Top Aluminum fork sleeves (2) to eliminate top out clunk

$28.00 Select options -

Bottom Aluminum fork sleeves (2) for early models provide hydraulic bump stop to eliminate bottom clunk.

$10.00 Add to cart -

Fork extension set for Turcite or original bronze bushings for smoother action (bushings not included). Also see aluminum sleeves and damper upgrade.

$79.00 Select options -

Fork extensions with slippery Turcite bushing set for smoother action. Also see aluminum sleeves and damper upgrade.

$199.00 Select options -

Fork extensions with Teflon upper and lower bushing set for smoother action. Also see aluminum sleeves and damper upgrade.

$169.00 Select options -

7″ Wrench for fork extensions with 4mm pin

$19.00 Add to cart -

Complete damper upgrade kit for Norton Roadholder forks. Also see aluminum sleeves and slippery bushings.

$49.00 Select options -

Ikon shocks (2) for Commandos, formally known as “Koni”

$299.00 Add to cart -

Ikon shocks (2) for Featherbed frames, formally known as “Koni”

$329.00 Select options

Showing all 10 results