Longer lasting Norton Cams for radiused lifters

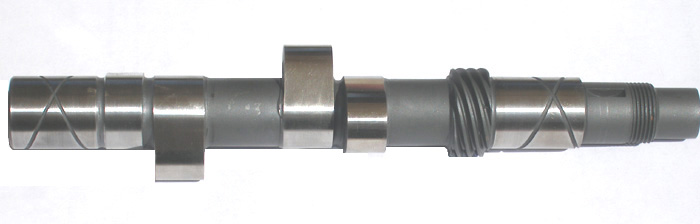

Increase the reliability of your street or race Norton and reduce the danger of valve float with JS Motorsport Radius Cam and Lightweight Lifter kits. I have personally tested these components beyond 8000RPM. Some short stroke racers have revved JS smooth ramp cams with beehive springs to 9000 RPM. JS cams either have hardwelded lobes or they are made with plasma nitrided billet steel. Either way – these are the highest quality, longest lasting cams you can buy. JS cams are superior because they are available with asymmetrical profiles which lowers the valve down onto the seat more gently (smooth ramp) to reduce wear on the valve train and avoid the dreaded “valve bounce” that can cause valves to tangle and destroy a motor.

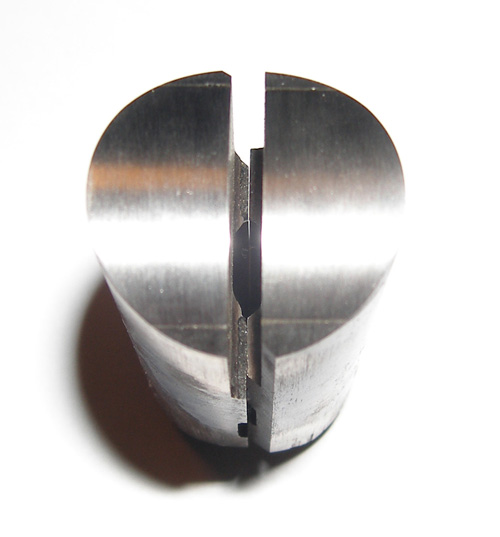

JS Motorsport Radius Cams are superior to standard flat lifter cams in all respects. The 1-1/8″ radius lifters allow the use of a broader cam nose (similar to a roller cam) to reduce stress and wear. See the broader nose of the JS cam on right (pointy stock nose on left). Note that high lift cams may require opening up the cam tunnel.

The durability and long life of our cams and lifters will save you money in the long run. This technology was initially developed years ago when factory sponsored Nortons were winning US dirt track races. We have refined this development to reproduce the pinnacle of performance for our vintage super bikes, for both street and track.

Cam comparison chart

| DESCRIPTION OF JS MOTORSPORT RADIUS CAMS | CAM LOBE LIFT | VALVE LIFT @ 0 clearance | DURATION MEASURED AT .040 | LOBE CENTERS | COMPARE TO FLAT LIFTER NORTON CAMS LISTED BELOW |

|---|---|---|---|---|---|

| JS0 - The perfect cam for stock street Nortons and stock broad power band performance with a slight overall improvement, stock springs OK. Smooth idle with good low end torque. BSA A65 Spitfire intake lobe profile on intake and exhaust. Same as Webcam 312 but for radiused lifters and improved ramps. | .345" | .390" | 268° | 104 | Close to Stock Norton Commando cam but with slightly more lift and duration. For 1-1/8" radiused lifters. |

| JS1 - hot street and all around racing for 4 or 5 speeds with strong mid range. Good idle but faster than stock. Requires racing springs for track. Great for 750s. This is a copy of the famous Axtell #3 cam but for lightweight radiused lifters. Similar to Webcam 312A but for radiused lifters and improved ramps. Note that Ron Wood achieved 84 hp with an Axtlell #3 cam in his 750 flat tracker. | .352" | .398" | 278° | 104 | Copy of Axtell #3 but for 1-1/8" radiused lifter. Performance similar to Megacycle 560NR and 560-00. Will fit 750 cases. |

| JS2 - full race PW3 copy with improved ramps for radiused lifters with excellent mid & Hi RPM power for all racers with 5 speeds and hot street 850s & 920s. Best all around roadrace cam. Requires racing springs. Hot rod idle. Maria Costello won Daytona 2011 in 750 vintage class with this cam & beehive valve spring kit. JS smooth ramp good for 9000 RPM with JS beehive springs and lightweight alum pushrods. | .375" | .424" | 282° | 105 | Similar to the great PW3 but for 1-1/8" radiused lifters. Improved with gradual ramps to eliminate valve bounce, prolong life and allow higher RPM (more info). Performance similar to Norton 2S (Combat) & 4S, Steve Maney cam. |

| JS3 - for 5 speed all out racers, D+/Sifton 460 grind with improved ramps. Rumpity idle. Beehive racing springs recommended. Used on factory sponsored Hi power US dirt track 750 short strokes. Good for 8500 RPM with JS beehive springs and lightweight alum pushrods. Top end race cam. Requires 7/8" radius lifters. | .400" | .452" | 292° | 106 | Similar to D+ (Sifton 460) and 7S but for 7/8" radiused lifters. Improved with gradual ramps to eliminate valve bounce, prolong life and allow higher RPM (more info). Good for maximum top end power. |

| JS4 - for 5 speed extreme racing. Sifton 480 grind with improved ramps. Beehive racing springs and lightweight alum pushrods recommended. Absolute monster of all Norton cams. Requires modfied 7/8" radius lifters (contact us). | .435" | .492" | 292° | 106 | Similar to Sifton 480. For 7/8" radiused lifters. Improved with gradual ramps to eliminate valve bounce, prolong life and allow higher RPM (more info). Good for maximum top end power. |

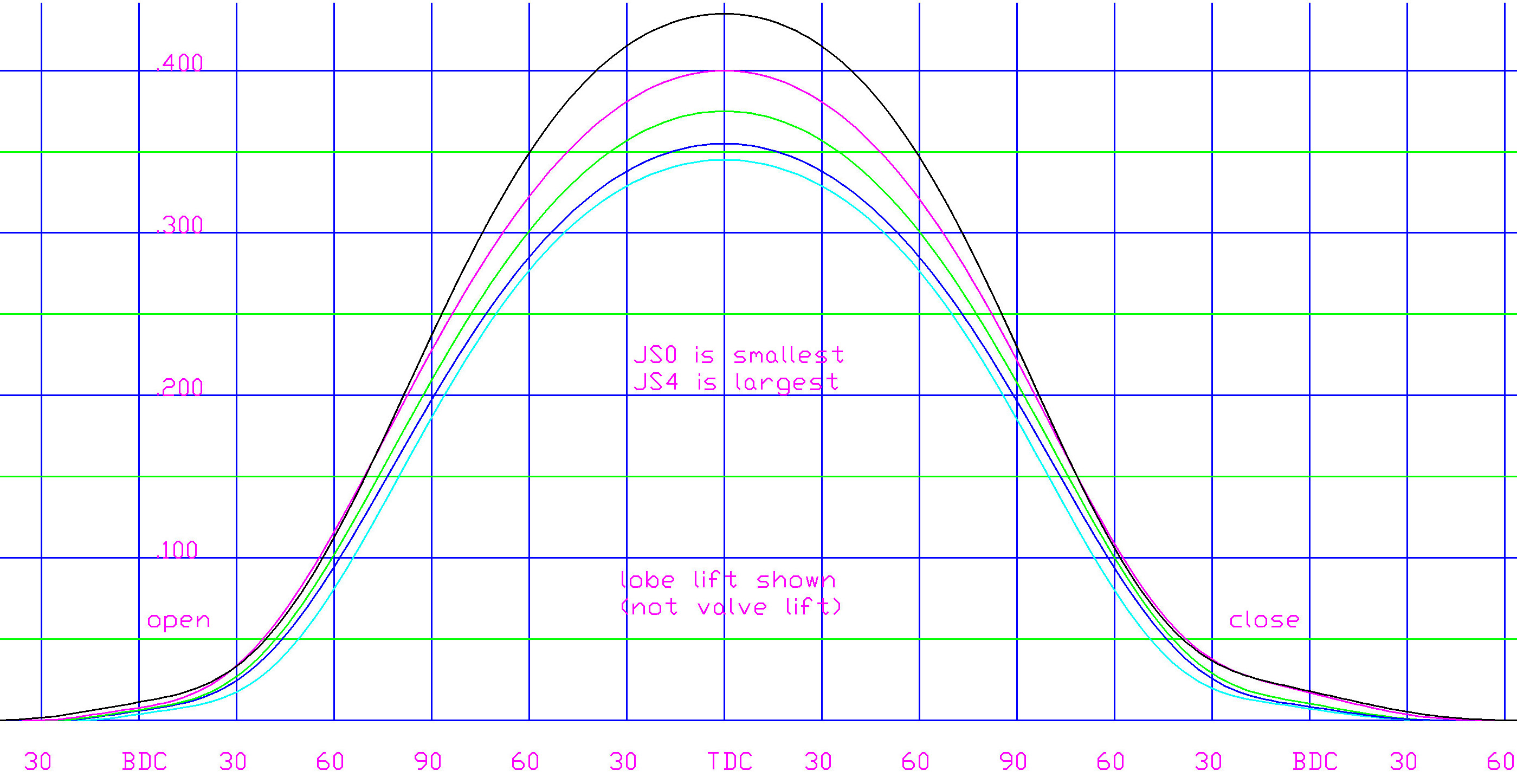

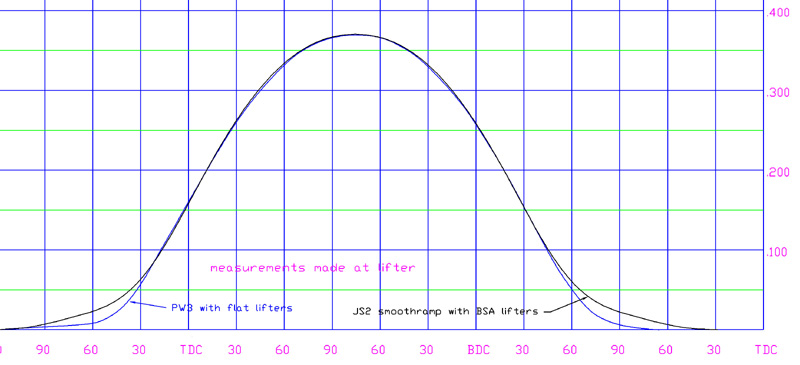

Profile graphs

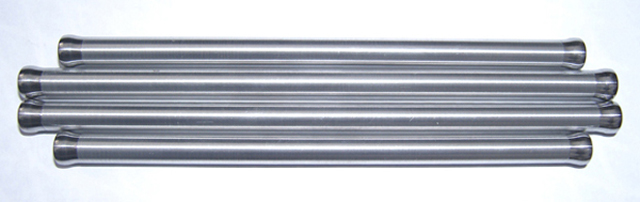

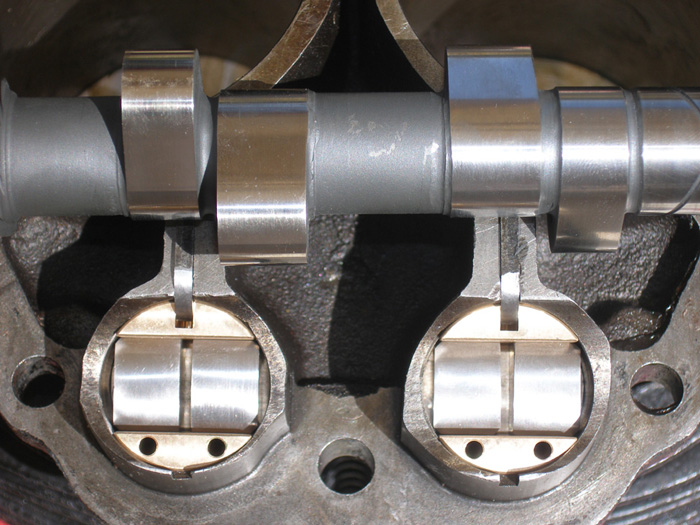

Lifters

Weighing approx 1/2 as much as original Norton flat lifters, JS Motorsport radiused lifters make your Norton more free reving while reducing stress, friction, wear and overheating of the valve train. Reducing the weight enables your valve train to operate more accurately and efficiently. Pushrod and rocker arm flex is minimized – giving you the full lift your cam was designed to deliver. This allows you to use more aggressive profiles than would normally be available on cams designed for heavy inefficient stock Norton lifters. Note that the oil holes in the tappet blocks drain oil directly onto the cam lobes as they rotate toward the tappets for ideal lubrication. Expect greater reliability and longer service (bronze block installation video).

Pushrods

JS2 vs PW3

Extended lifters for the JS4 Monster cam

The extra lift and duration of the JS4 cam (Sifton 480 with improved ramps) requires special modified BSA lifters as shown below (contact us). The bottom rectangular area of the lifter is taller so there is more overlap in the bronze lifter block.