One way reed valve crank case breather

Pumping out positive crank case pressure and leaving a slight negative pressure is a great way to eliminate oil leaks. This simple breather uses a stainless spring steel reed valve (street and track tested). Body is machined from highest quality 7075 Alum. Stainless steel fasteners. Easy installation with no machining necessary. Available in several versions – 750 left case vent, 850 rear timing side mount, Combat style lower case mount and sump plug mount (see breather demo)

(see pre 71 Commando version with crossover tube)

750 LEFT CASE VENT MOUNT:

Replaces the early 750 Commando and Atlas vent on the left case. A drop in kit but you should remove the original cam rotary valve with spring and plug timing chest vents for best efficiency if the motor is already apart. See diagram for plugging vents as shown at bottom of page.

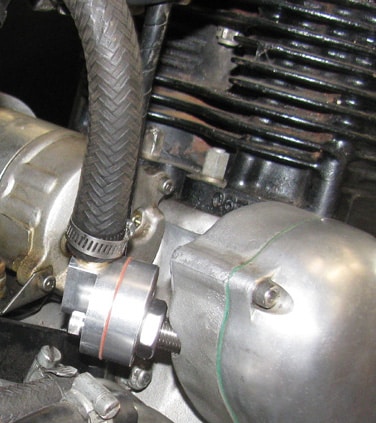

850 Mk2 TIMING CASE MOUNT:

Replace the original 850 MK2 timing case vent tube with the one way reed breather valve as below.

850 Mk3 ELECTRIC START TIMING CASE MOUNT WITH AFTER MARKET STARTER:

Replace the original 850 MK3 timing case vent tube with the one way reed breather valve as below. Fits Mk3s with shorter aftermarket starter as below (original airbox may need replacement).

850 Mk3 ELECTRIC START TIMING CASE MOUNT WITH ORIGINAL PRESTOLITE STARTER:

Replace the original 850 MK3 timing case vent tube with the one way reed breather valve as below. Special angular fitting allows it to fit Mk3s with original prestolite starter (original airbox may need replacement).

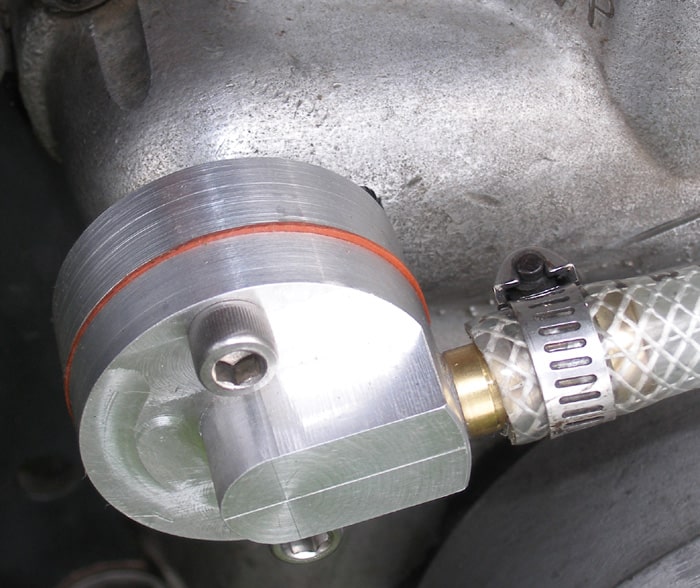

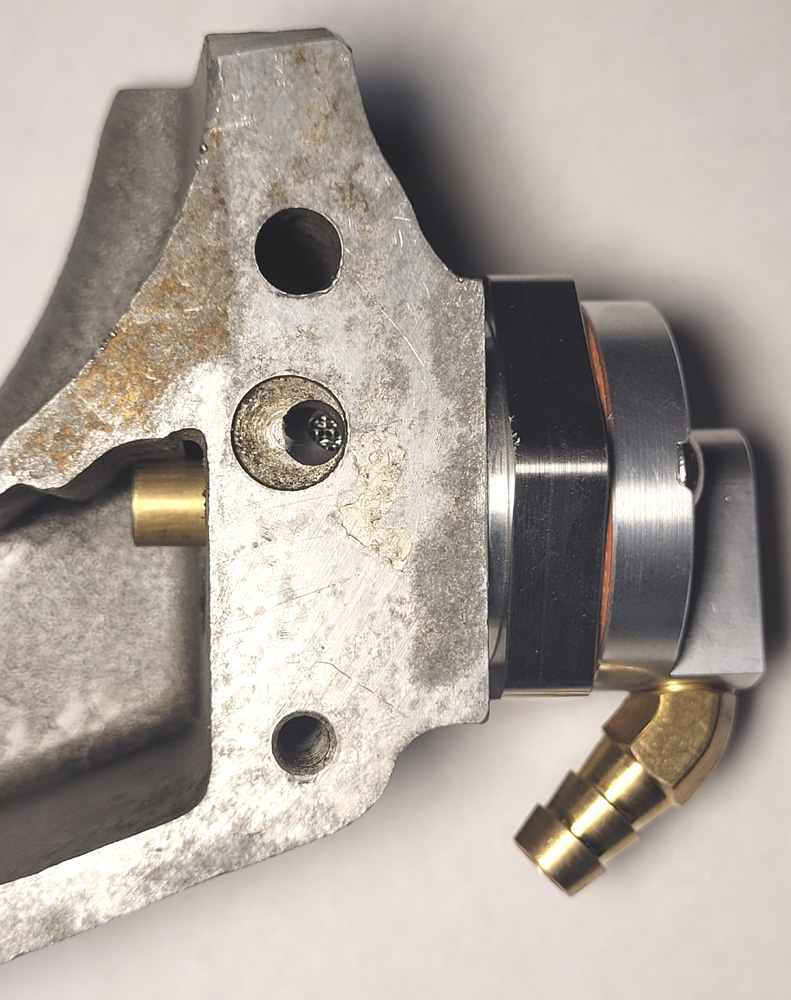

COMBAT STYLE LOWER REAR CASE MOUNT:

Bolts right up to Combat and aftermarket heavy duty cases (no machining necessary). Other cases can be modified to use this breather (page down). Only two screws are necessary. Reusable gasket provided (will not clear TTI transmissions).

Combat and some heavy duty aftermarket cases are already drilled and threaded to accept the JS breather as below

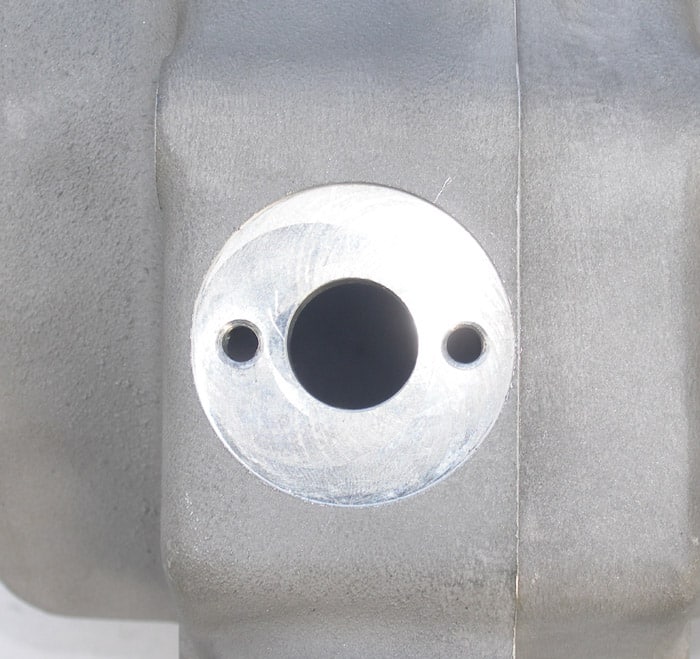

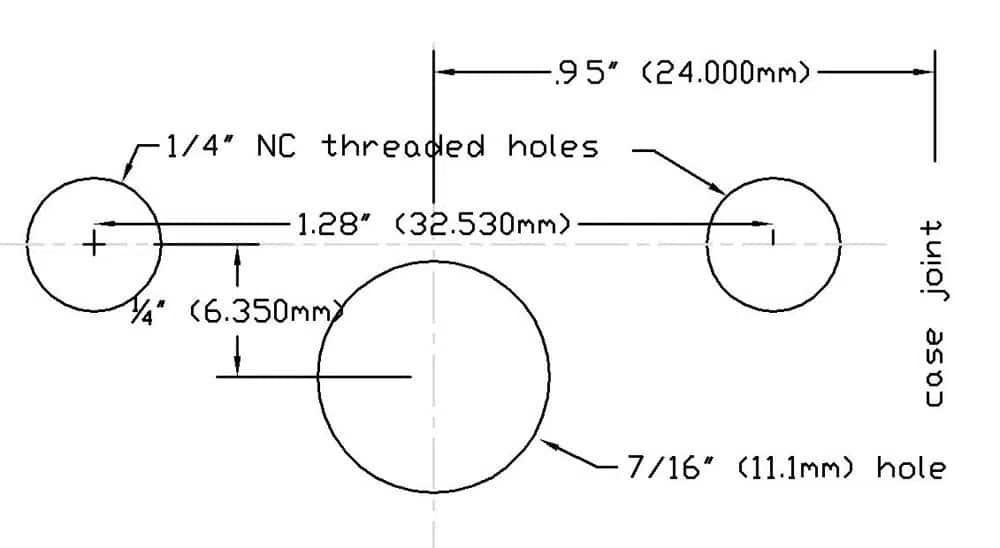

OPTIONAL – For those with other types of cases who want the lower rear case mounted reed valve breather – you must drill and tap two small holes and one larger breather hole in the lower left case as shown below.

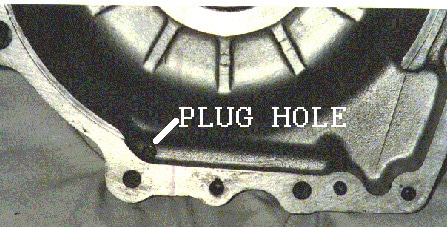

ORIGINAL COMBAT CASES – Cut away the web to expose the rear oil pickup hole in the right side case (left photo below). Then plug the forward pickup hole (right photo below). You must vent the reed valve into the oil tank.

FITS MK1 & 2 850s WITH THE CROWDED OIL DAM – Actual MK2 case shown below. Choose “Mk1 & 2 850s with oil dam” when ordering.

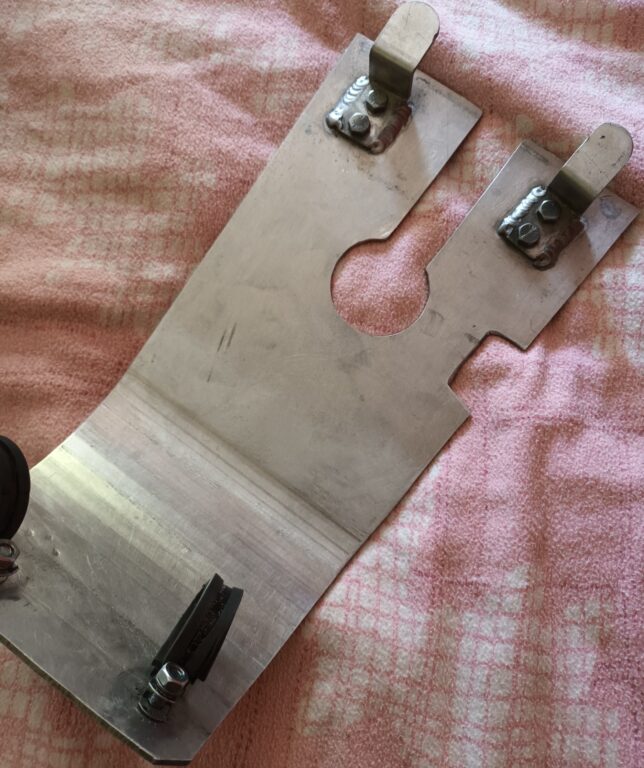

Some P11s have a bash plate under the sump. If so then you will have to remove it or cut out a slot to clear the breather as shown.

INLINE BREATHER FITS ALL MODELS – Splice this into the breather hose between the motor and the oil tank. Works for any vertical twin or single cylinder motor.