To make your Norton truly oil tight you need the following ingredients:

Use Permatex Motoseal #29132 on all case joints that don’t use gaskets (same as grey Yamabond etc).

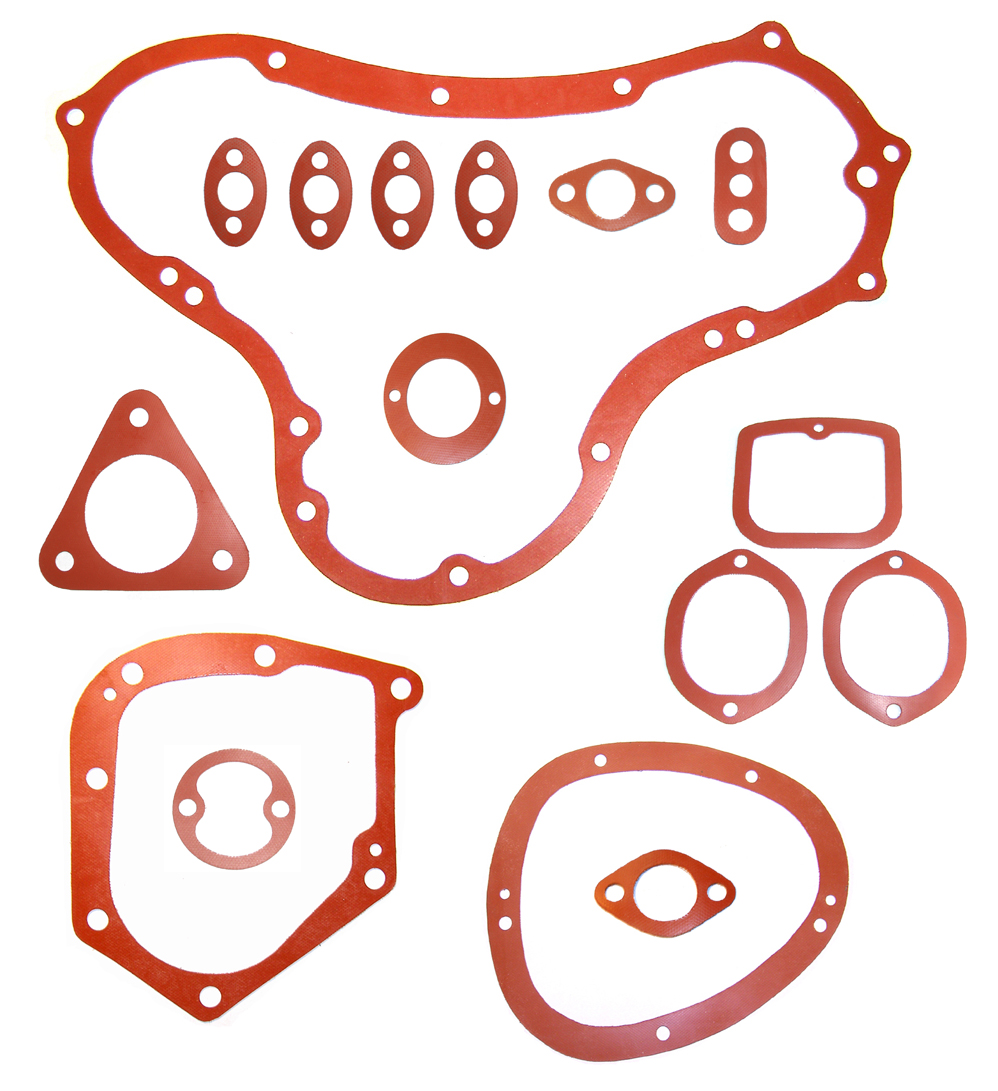

Use JS fiberglass reinforced silicone gaskets throughout engine/tranny as shown below and described here (go here to order gaskets).

If you use a copper headgasket then use pliobond sealer and fine copper wire around the pushrod tunnels as described here (more info).

Use a one of several JSM one way reed valve breathers to eliminate crankcase pressure (more info).

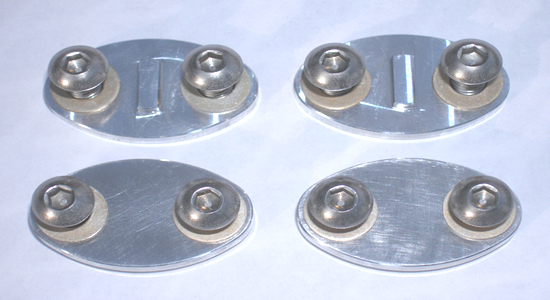

Switch to JSM one piece rocker spindle covers (go here to order rocker spindle covers).

Use special oversized viton Orings throughout engine/tranny as shown below (order Orings here).